History of Matcha and Aiya

Introduced from China to Japan.

And now, from Japan to the world

Introduced from China to Japan.

And now, from Japan to the world

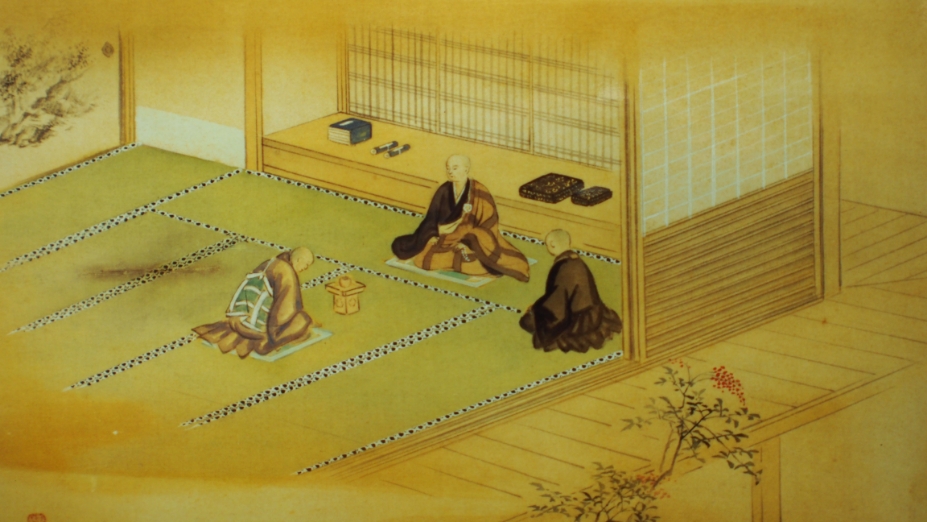

It was introduced to Japan from China in the 12th century, and later developed as a tea ceremony.

During the Muromachi period, the tea ceremony was popularized by Zen monks, and the tea ceremony flourished as an art form. During the Edo period, tea parties and tea rooms became popular among the common people. In the 19th century, tea manufacturing technology advanced and matcha became popular. Nowadays, it is gaining worldwide attention due to its traditional flavor and health benefits.

This is the history of Aiya along with Nishio's matcha.

The history of “tea” is told to have begun in China in around 2700 B.C. Initially, Chinese people drank tea as a type of medical herb.

Japanese envoys and monks brought back tea seeds and tea culture from Tang Dynasty.

Tea in those days was treated as medicine in Japan and was only available to aristocrats and the upper-class.

In the early days of Heian period, Japanese envoys such as Saicho brought back tea culture from China.

Japan actively began tea cultivation in the late Heian period.

Initially, tea was used as medicine among aristocrats, later it was gradually introduced to commoners and tea cultivation spread through out the nation beginning with Kita-Kyushu region.

In 1191, Eisai, the founder of Rinzai Sect, brought tea seeds back to Japan from China and introduced the matcha method of adding tea powder to hot water and stirring.

He popularized tea in samurai society when he offered a cup of tea and the “Kissa Yojoki”, the treatise describing the benefits of tea, to Sanetomo Minamoto, the shogun of that time.

Matcha spread among commoners during Nambokucho period. During the Muromachi to the Azuchi-momoyama period, Juko Murata, Joou Takeno and Sen no Rikyu introduced the new style of tea ceremony called “Wabicha”. After dissemination to the samurai society, “Sado” was established as known today.

Shoichi Kokushi, the founder of Jisso Temple, brought tea seeds from Song Dynasty and planted the seeds in the precincts of his temple in 1271. That was the beginning of tea cultivation in Nishio-shi, Aichi-ken where AIYA is located. Matcha cultivation was established owing to Yahagi river's abundance of water, fertile ground and mild climate of the area. Today, Nishio is one of the biggest tea producers in Japan.

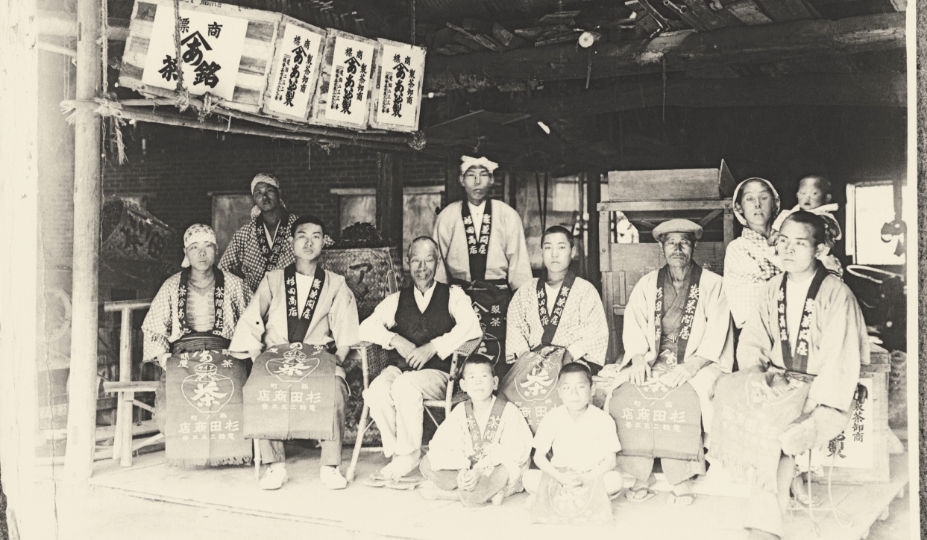

Full-scale tea cultivation began in Nishio in around 1872. During this time Japan ended the national isolation and started exporting raw silk and tea. In midst of such social background, there was a growing trend of cultivating tea in Nishio and many people in Nishio were ambitious in tea business. Aijiro Sugita and Tsurukichi Sugita developed tea fields in Mt. Inari area. This is where AIYA originated.

The feature of Nishio tea is that they aimed to produce high-class tea exemplified by Gyokuro from the beginning. To produce the best tea. That was the strong aspiration among Nishio people. In 1888, Aijiro Sugishita found the Sugishita Shoten, a tea and indigo plant production company.

In mid-19th century when Japan was opened to the world, major export goods was raw silk and tea. In midst of such background, there was movement to develop the tea business in the Nishio region, which is blessed with a natural environment of good water quality, soil, and weather that is suitable for producing tea. During this period in 1888, the first president Sugishita Aijiro found Sugishita Shoten, a tea and indigo plant production company.

The feature of Nishio Tea founded in early Meiji era was that they aimed to produce high-quality tea from the very beginning. This was the start of the foundation for good tencha production, which later became the raw material for matcha.

In 1904, the Hazu-gun Seicha Doshikai was organized with tea field owners of Kamimachi (where AIYA headquarters is located). The organization has been taking initiatives for the tea production business by holding tea fairs and conducting tea production training programs for improved technology. Technology and quality for high-class tea was further improved and sales channels were expanded. Customers expanded from within the prefecture to Kanto and then to Kansai areas.

Tea producers in the Nishio area including Sugita Shoten, aimed to produce tencha with higher commercial value. They established a cultivation technique of covering the tea trees before harvest.

Aiya Tea Store Limited Partnership Company was established in 1922. When the appointment of the second president, Aijiro, the indigo production and sales that started since early Meiji era was discontinued and the company focused on tea production, and made efforts to improve tea production technology and to expand sales channels. During this time, Nishio Tea genuinely started to change from gyokuro to tencha.

Focusing on only tea, reinforced the organization in many aspects. Productivity increased by constructing a new office building and tea production factory. After the Mikawa tencha machine was invented in 1930, production increased and Nishio developed dramatically as a matcha producing area.

At the end of the Greater East Asia War, tea fields were hit by a crises of having to convert the fields for growing potatoes and wheat which will serve as food. In addition, the Tonankai earthquake occurred in December 1944 and the Mikawa earthquake occurred in January 1945. Nishio-shi was near the epicenter and was hit by a seismic intensity of 7. The office building was completely destroyed. The war ended in August 1945. The tea producers in Nishio continued to produce good tea in spite of their suffering. Four years later, contracting tea field area exceeded 70 hectares and tencha production grew stably.

In 1950 when Japan was in the reconstruction mode, AIYA Limited was established. The third president, Aijiro, inaugurated and boosted production capacity.

Challenged new market development in around 1960. A new path was found by changing the fixed idea of matcha as a drink. The company aimed for the expansion of sales channel for matcha as a food processing material.

The third president Aijiro cultivated tencha fields in the mountains of Toyota-shi, Aichi-ken (formerly Shimoyamamura). There, efforts were made to produce Japan's first organic matcha, which at that time was considered very difficult. The tencha fields were destroyed over and over again from pests, rain and the sun. The forth president Aijiro realized the organic matcha both human-friendly and environmental-friendly.

AIYA started exporting to North America in 1983 after expanding sales channels nationwide and boosting production. Japan started to disseminate matcha culture to the world in this year.

Washoku is well-accepted in many countries worldwide with growing support for health consciousness. Japanese tea and matcha have also been universally recognized. One can say that the word “MATCHA” is already known universally. Tea, with its origin in China, is now exported worldwide from Japan.

AIYA shifted the appraisal standards of matcha to scientific analysis from relying on human sense and established a Quality Control Department in 1985. This enabled to indicate matcha quality objectively in figures. The objective data management ahead of its time contributed largely to exports and market expansion in the field of processed foods.

In 1989, AIYA at the 100th anniversary established a raw material supplier, Meihoenseicha, Ltd. This year, the fourth president, Aijiro Sugishita, inaugurated and stabilized production and improved quality with the raw material producers.

AIYA obtained an organic cultivation certification from JONA (Japan Organic and Natural Foods Association). With ceaseless trials and errors, organic cultivation of tencha succeeded, which was said to be impossible at that time.

In 2001, AIYA established AIYA America, a local subsidiary, (transferred to Los Angels in 2004). An European subsidiary was also established in Wien, Austria.

In 2002, AIYA obtained certifications for organic tea from OCIA (American organic certification), IMO (European organic certification), and Kosher (Jewish law for foods).

In the same year, AIYA obtained ISO 9001 assuring qualities in all stages of production (designing, development, manufacturing, installation and supplementary services). This certified that quality is assured even in the stages of designing and development as well as manufacturing and services.

Following the American subsidiary, AIYA established an European subsidiary “AIYA Europe GmbH” in Wien, Austria in 2003 (transferred to Hamburg, Germany in 2008).

AIYA established a Chinese subsidiary “Zhejiang Aiya Tea Co., Ltd.” in Zhejiang, China in 2005 (transferred to Shanghai in 2013). Thus, hubs in the American continent, European continent and Asian continent were established respectively.

In 2005, AIYA established a new Quality Control Department along with the introduction of new system and realized safety improvements. AIYA provides specifications that cover requirements from customers such as analysis of general live bacteria, colon bacilli, mold, yeast, tea component, and inspection of agrochemicals residue.

In 2007, AIYA achieved “Superior”, the best grade both for the matcha refining factory and matcha production factory in the AIB food safety audit. AIB conducts guidance and inspection in accordance with “Consolidated Standards for Inspection” made by AIB uniquely based on various global laws and regulations. The rating results and certifications assures our worldwide customer the safety of our matcha products.

In 2007, AIYA was selected as one of the best “300 energetic SMEs in manufacturing” and was awarded the grand prize; the excellent company prize at 41th Good Company Award in November of the same year.

In 2008, AIYA obtained ISO 22000 certification (Food Safety Management System). This objective certification of safety standards ensured the delivery of safe products to customers.

AIYA has developed matcha which preserves its color even in the secondary process. That was a longtime dream of the matcha industry. In 2009, the longtime studies generated the “Greeminal series”, color preserving oil-coated matcha.

In 2011, AIYA established “Saijoen”, a sweets brand. Development and sales of matcha sweets began with the concept “exciting, genuine, friendly” to provide some motivation for our customers to become more familiar with matcha.

AIYA obtained FSSC 22000 in 2014. With this a system for accelerating exports to developed countries was established.

(Certification for matcha production at the main factory and Yonezu factory. From 2017, we added the production of powdered tea to the scope of certification. Acquired at the Kyoto factory in 2018. From 2023, the production of sugar mixtures will be added to the scope of certification for the main factory and Yonezu factory.)

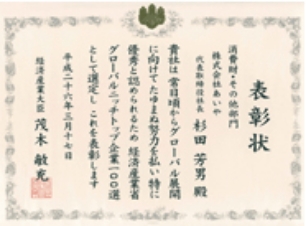

2014年、(株)あいやは経済産業省「グローバルニッチトップ企業100選」に選出されました。「抹茶」の分野において国際的に高いシェアを確保し、良好な経営を実践していることが評価されました。

In 2014, we obtained Halal certification, which guarantees that the food is permissible according to Islamic teachings.

In 2016, we obtained Non-GMO certification, which indicates that it is a non-genetically modified food.

In 2016, we received gluten-free certification, which guarantees that our products do not contain gluten such as wheat, rye, oats, or barley.

In 2016, Aiya Co., Ltd. received the Chubu Bureau of Economy, Trade and Industry Director's Award at the 1st 100 Year Company Award from the 100 Year Management Association. The company was recognized for its management philosophy as a long-lived company with over 100 years of history in Japan, and as an excellent company that serves as a model for other companies in the region.

Since 2017, we have obtained Rainforest Alliance Certified to source, process, and manufacture tea from certified farms. At certified farms, farmers follow more sustainable farming practices, protect the environment, ecosystems, and natural resources, and work on improving their rights and livelihoods.

(The Head Office Factory, Second Yonezu Factory, and Meihouen have obtained certification.)

In 2017, we established a local subsidiary, AIYA Thailand, in Bangkok, Thailand.

In 2017, we established the Aiya Kyoto Factory in Ujitawara Town, Kyoto Prefecture.

In 2017, Aiya Co., Ltd. opened the Matcha Museum Saijoen “Waku Waku” on the premises of the Aiya main store in Nishio City as a facility where you can fully enjoy the charm of matcha with all five senses. Additionally, we opened the Saijoen Matcha Cafe at Global Gate in Sasajima, Nagoya, which serves drinks and sweets made with matcha grown at our own factory.

In 2018, Aiya Co., Ltd. was certified as a “Regional Future Driving Company” by the Ministry of Economy, Trade and Industry. We were certified as a company that leverages the characteristics of the region to create high added value and develop businesses that strongly drive regional economic growth.

In 2019, Aiya Co., Ltd. received the Aichi Service Award “Special Award”. We opened an “experience-based matcha specialty museum” where you can enjoy matcha with all five senses, and were highly praised for greatly contributing to the promotion of the local brand “Nishio Matcha”.

In 2020, overseas sales of matcha exceeded domestic sales. This is the result of having established overseas subsidiaries in Los Angeles (USA), Hamburg (Germany), Shanghai (China), Bangkok (Thailand), Thailand, and actively selling matcha and green tea not only in Japan but also around the world.

In 2021, Aijiro Sugita (4th generation) received the Order of the Rising Sun with Small Cordon at the spring conferment of decorations.

He was recognized for his contributions to the development of local commerce and industry.

In 2021, we opened Saijoen Matcha Cafe in Dai Nagoya Building, Nakamura Ward, Nagoya City, and Saijoen Matcha Cafe in Aeon Mall Nagoya Noritake Garden, Nishi Ward, Nagoya City. Additionally, in 2023, we opened Saijoen Matcha Cafe at Aeon Mall Toyokawa in Toyokawa City, Aichi Prefecture.

In 2022, in order to further improve corporate value and achieve sustainable growth, we established Aiya Holdings Co., Ltd., which manages overseas subsidiaries and matcha manufacturer Aiya Co., Ltd.

In 2024, we built a new warehouse in Yonezu-cho, Nishio City for the purpose of business continuity planning (BCP).

This warehouse is equipped with large refrigerators that can properly store raw materials, and is designed to minimize damage to business assets in the event of an emergency such as a natural disaster, while enabling us to continue or quickly restore our core business operations.

PageTop

PageTop